Categories

MORE THAN 500 Solutions...

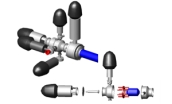

Simple Pigging Stations(in line –off line stations)

Compatible with most sanitary “Pigs” available in market. Material available for Pharma/food FDA. Upgrade Kit for existing systems. Full drainable system. Compact design. CIP/SIP.

Automated Cluster

Compact but customizable design - Up to three layers - Horizontal or Vertical - Minimized footprin - Multiple to multiple connections - Automated functionallity - Fully drainable.

Single Module CIP skids

Fixed skid covering any process needs - 3 to 5 steps - Fully drainable - Self cleaned

DI Water

Units from 1-50m3/h, Storage tank compination with ozon or hot water

Super Heated Hot Water

High temperature without steam.

Weight Batching Systems

Move virtually any bulk material, from any upstream source, to any downstream destination

Learn more

Flexible Screw Conveyors

Move efficiently and with flexibility bulk materials ranging from large pellets to sub-micron powders — both free-flowing and non-free-flowing — with no separation of blended products.

Learn more

Pneumatic Conveyors

Satisfy an exceptionally wide range of bulk conveying applications that range from single-point "up-and-in" installations to cross-plant systems with multiple pick-up/discharge points and automated controls.

Learn more

Bag Dump Stations

Reduce material waste and eliminate the need to clean a remote dust collection site, while protecting workers and preventing plant contamination.

Learn more

Bulk Bag Discharge Systems

Eliminate the drawbacks of outdated designs while dramatically improving convenience, safety and cleanliness.

Learn more

Tubular Cable Conveyors

Route vertically, horizontally or at any angle, through small holes in walls or ceilings, with configurations range from basic systems with one material inlet and one discharge, to systems routed in several directions over hundreds of feet/meters, with multiple material inlets and outlets.

Learn more

Portable Conveying Systems

Fit through tight spaces with reduced footprint and maneuver through narrow aisles and around corners providing conveying capabilities all around, according to your needs.

Learn more

Combined Conveying Systems

Combine various systems to achieve endless caabilities in bulg material handling.

Learn more